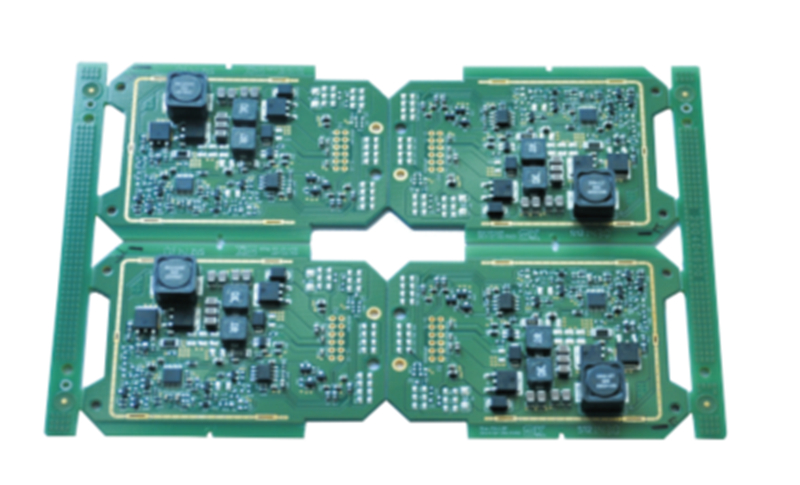

SMT ke thekenoloji ea kopano ea holim'a metsi, e leng moloko o mocha oa theknoloji ea kopano ea elektronike e entsoeng motheong oa theknoloji ea potoloho e kopantsoeng ea lebasetere.Kajeno re tla hlahisa palo yohle ya mehato yaTlhahiso ea SMTmokhoa oa line.

Phallo ea ts'ebetso ea mohala oa tlhahiso ea SMT e ka akaretsoa joalo ka:

Ho hatisa (sekhomaretsi se sefubelu / pente ea solder) --▷ "tlhahlobo (boikhethelo ba SPI kapa tlhahlobo ea pono) --▷"ho beha (ho beha lisebelisoa tse nyane pele ebe u beha lisebelisoa tse kholo: mochini o behang Chip o lebelo le phahameng + mochini o behang IC o sebetsang ka bongata. ) --▷"hlahloba (boikhethelo AOI optical optical or visual inspection) --▷ " (red glue curing) --▷ "reflow soldering (sebelisa hot air reflow soldering for surface mount components welding) --▷ "hlahloba ((ka e arotsoe ka ponahalo ea AOI ea tlhahlobo ea mahlo le tlhahlobo ea tlhahlobo ea ts'ebetso) --▷ "tokiso (ho sebelisa lisebelisoa: tafole ea solder le tafole e chesang ea moea o chesang, joalo-joalo) --▷ "plug-in (ka-hole components automatic plug-in kapa manual plug-in)--▷ "wave soldering (ho sebelisa wave soldering bakeng sa plug-in welding) --▷ "ho hloekisa --▷ "hlahloba (boikhethelo ba AOI optical optical or visual inspection) --▷ "tokiso (ho sebelisa lisebelisoa : tafole ea solder le moea o chesang Tafole ea desoldering, joalo-joalo) --▷ "Karohano ea mapolanka (ka letsoho kapa mochine o arolang oa boto bakeng sa ho arohana ha mapolanka) --▷" Teko (e ka aroloa ka tlhahlobo ea ICT in-line le tlhahlobo ea tlhahlobo ea ts'ebetso ea FCT )--▷" Tlhokomelo (ho sebelisa lisebelisoa: tafole ea solder le tafole e senyang moea o chesang, joalo-joalo)

Ka holimo ke mehato ea ts'ebetso ea SMT, e le moloko o mocha oa theknoloji ea kopano ha ho etsoa lihlahisoa tsa elektronike, mohato o mong le o mong oa eona o tšoana le tlhahiso ea PCB, e nang le likarolo tse thata le tse ntle, ke tšepa hore sehlooho sena se ka u fa boitsebiso bo itseng. .

Nako ea poso: Oct-22-2022

Youtube

Youtube